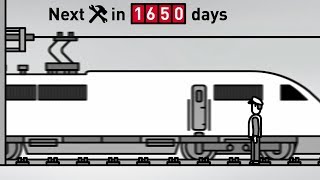

An overhaul and maintenance company for underground trains in the UK had a requirement to reduce service costs of traction motor bearings by increasing the time between overhauls whilst maintaining reliability. A review of greasing procedures at initial build and maintenance was undertaken by NSK Engineers, with improvements proposed, accepted and documented. Additionally, NSK performed a Condition Analysis of bearings that had completed 6 years in Service. Using this information combined with NSK bearing lifetime analysis techniques, the overhaul period was increased from 4.5 years to 5.5 years, aligning with other components on the train. Visit our website to learn more about this Success Story: https://www.nskeurope.com/en/success/underground-train-traction.html About NSK Europe: NSK products and solutions are everywhere where something is moving – even deployed under the hardest of conditions. Our high precision roller bearings and ball bearings are spinning away in wind turbines and machine tools, our linear systems are hard at work in production lines. As a worldwide strategic partner to the top automobile manufacturers and suppliers, NSK provides solutions that offer more performance while taking up less space. Intelligent steering systems, engine, wheel hub and transmission bearings – our OE car parts not only ensure more efficient use of fuel, but also increased safety for automobiles. Connect with NSK Europe: Website: https://www.nskeurope.com LinkedIn: https://www.linkedin.com/company/nsk-europe/